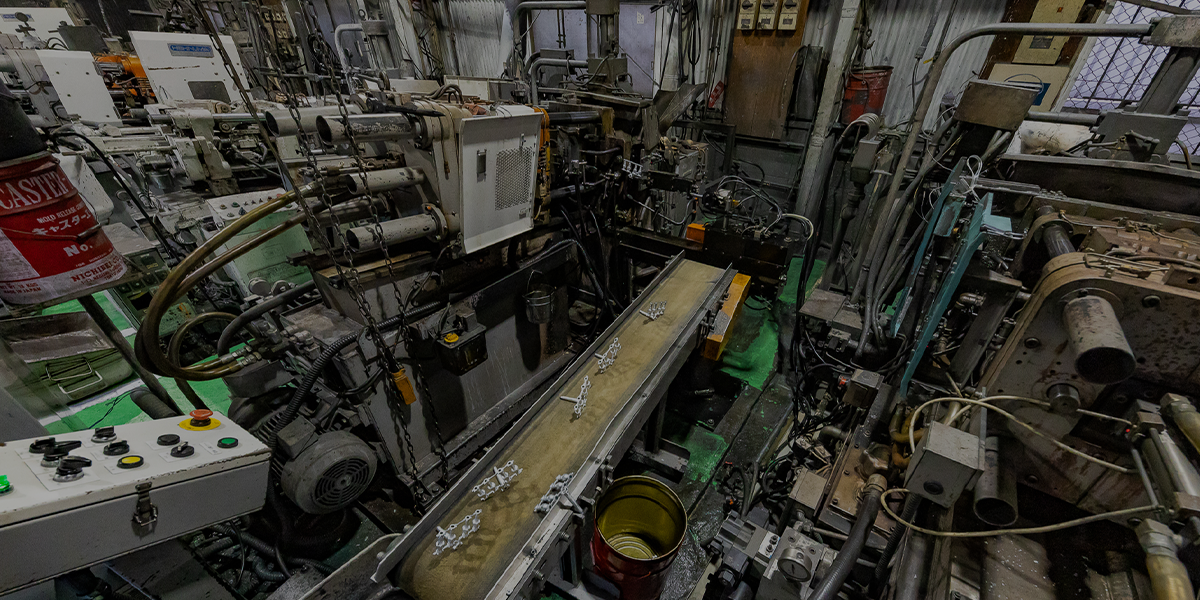

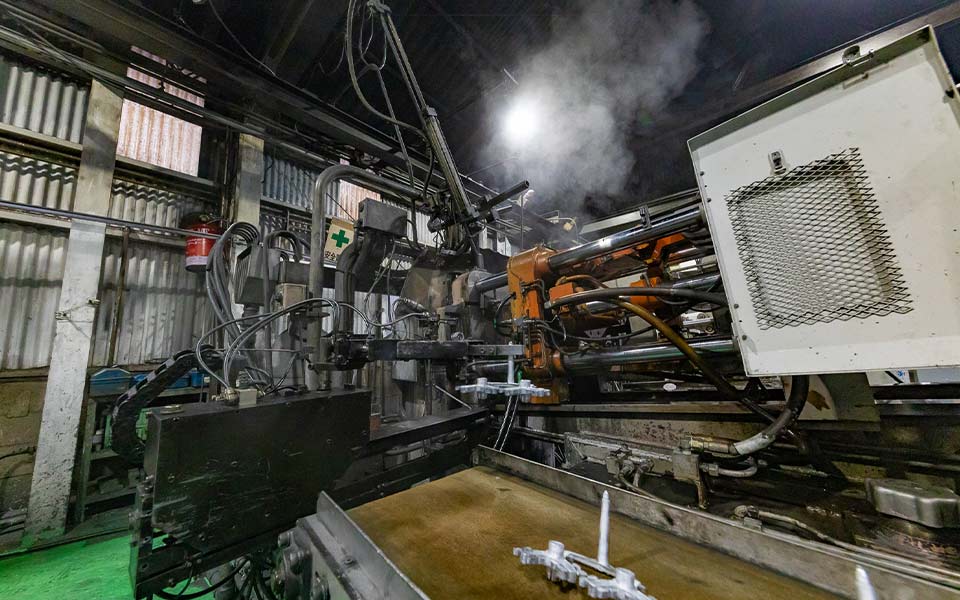

Die casting is a casting technology in which an alloy melted at high temperature gets formed instantly by pouring into a precision mold at high speed and high pressure.

We specialize in zinc die casting, and are highly capable of manufacturing large quantities of products with complex shapes and high dimensional accuracy. Furthermore, a high level of wall thinning facilitates molding after casting. Reduction of the machining process as much as possible will also save time.

Another reason why zinc die castings are widely used is that the life of the die is so long that hundreds of thousands of pieces can be manufactured with one die due to the nature of zinc having a low melting point and less burden on the die.

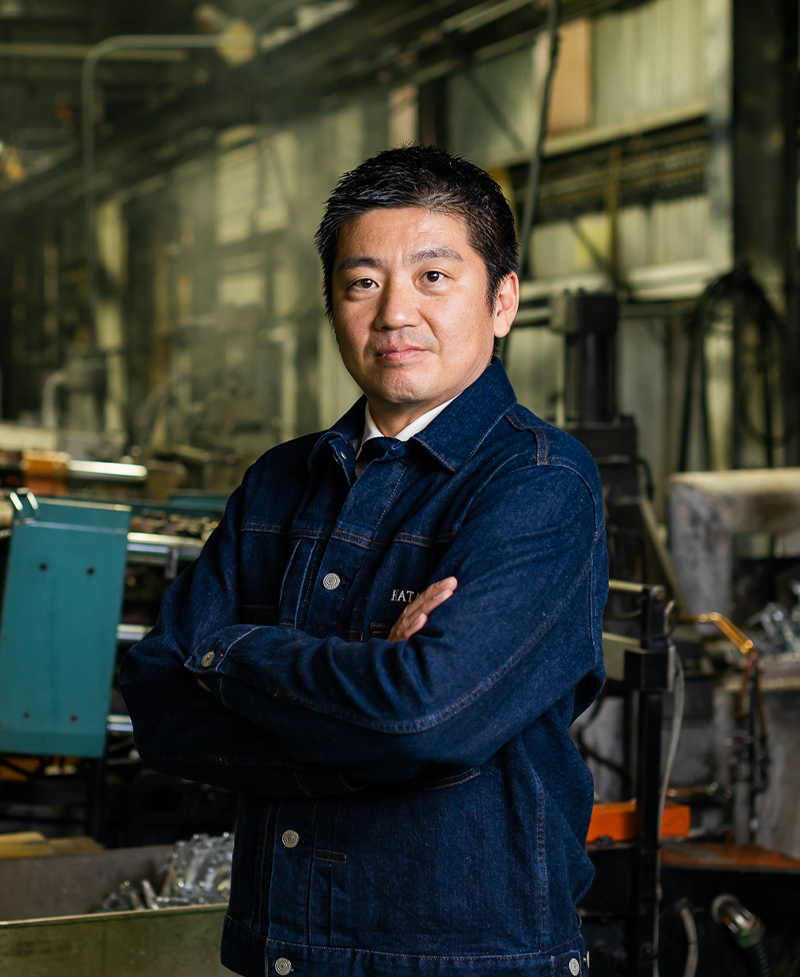

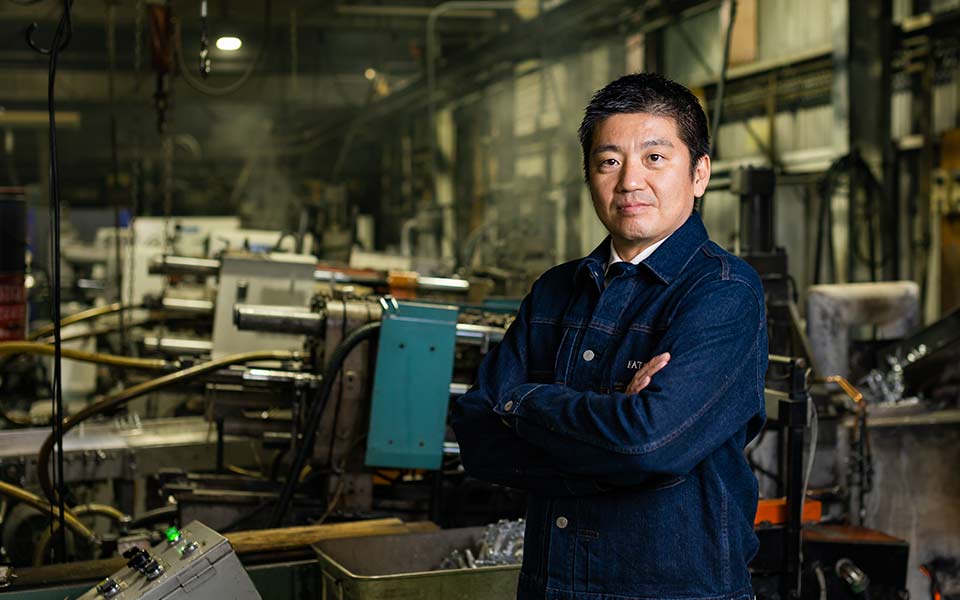

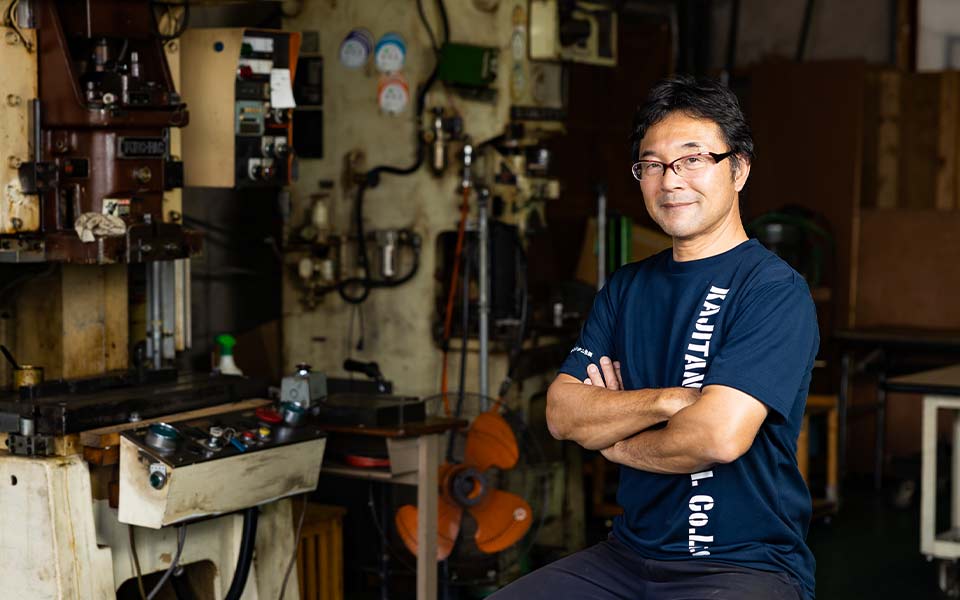

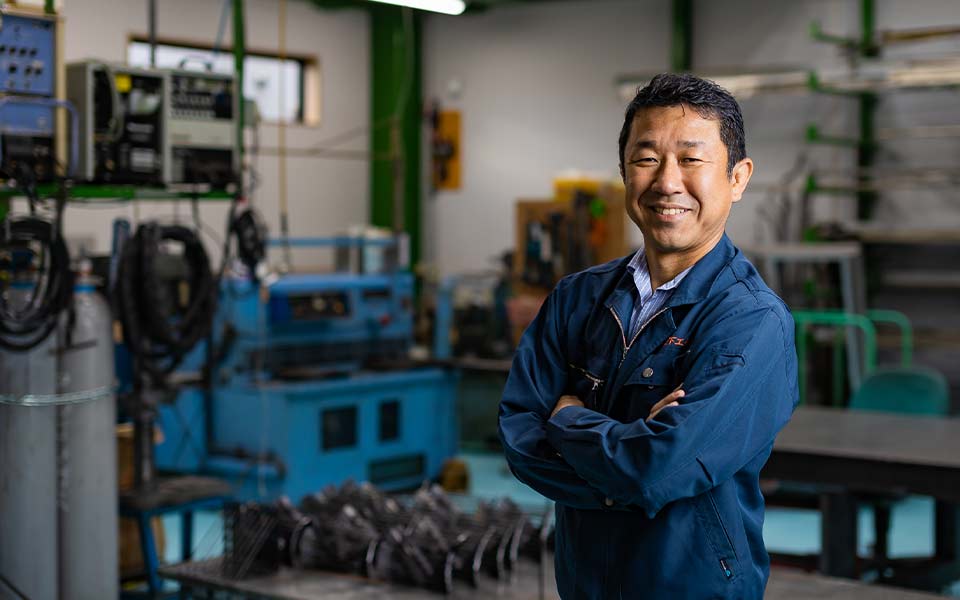

As a company with a large number of employees from over the world, we have a policy that focuses on enhancing communication among employees, by encouraging reporting, communication, and consultation through daily morning and end-of-day meetings and weekend meetings. We focus on setting goals for each department and making the necessary improvements to achieve those goals. In addition to daily maintenance of machines and molds, we make it a habit to keep the workplace tidy and orderly, and each of us develops the humanity to speak and act on our own initiative.