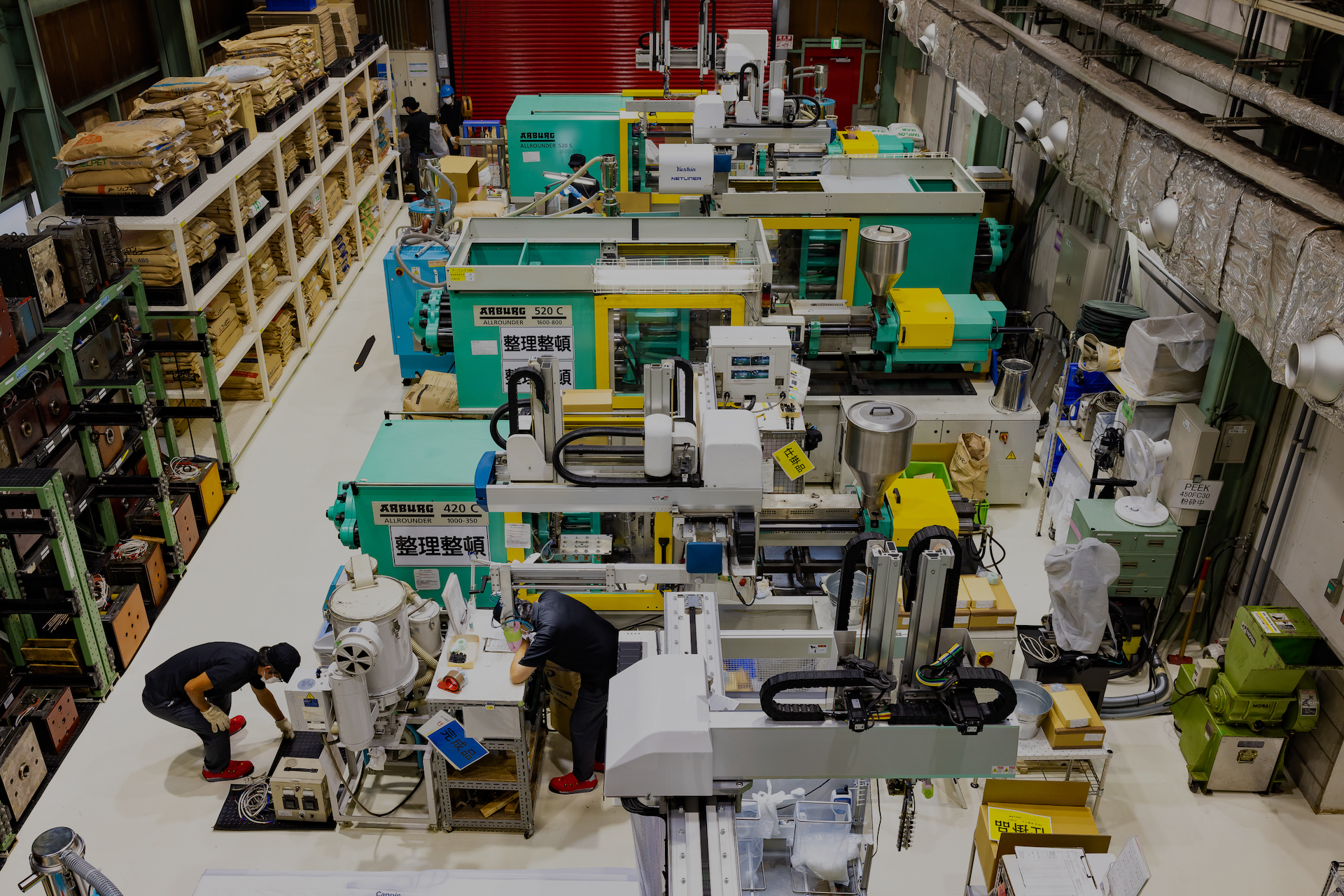

Founded in 1958, the company started with compression molding of thermosetting resins such as phenol, but in 1988, it began making molded products that cannot be imitated by other companies. That is the super engineering plastic represented by PEEK, which at that time no one knows in which field it should be used. It was a frontier situation where no one can ask about its molding method. First of all, we had no choice but to consider updating to an injection molding machine that can mold such resins, and in the end we introduced an injection molding machine made by a German company, ARBURG, which is the most advanced in the field. After many twists and turns, PEEK began to be used in liquid crystal manufacturing equipment from around 2000, and then used in semiconductor manufacturing equipment. Finally, the times wanted Daipla’s molding technology. Nowadays, we have reached the point where we consume the largest amount of PEEK resin from a certain Japanese manufacturer. From now on, in order to utilize this technology and acquire cleanliness that can be marketed in the medical field, we have completely renovated the factory and office, and are focusing on creating human resources and environment to cultivate the technology further more. In October 2021, we invited instructors from the United States to hold a workshop for the growth of all people working in the company, including business owners, to lead a rich life through work. We would like to continue to strive as a company aiming for NEXT ONE.